Multistage Pump

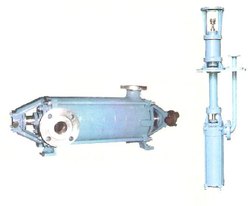

Horizontal Multistage Pump

We supply Entity Hydrodynamic Brand Multistage Pumps.. Below are general Specs and application areas of these pumps.

Material of Construction

| Delivery Size :- Up to 50 mm |

| Rate of Flow :- Up to 60 m³/h |

| Head :- Up to 300 m |

| Temperature :- Up to 180ºC |

| Working Pressure :- Up to 50 kg/cm²/td> |

APPLICATIONS / LIQUIDS HANDLED

The ENTITY make vertical submerged multistage pumps are most suitable for applications such as firefighting, booster service, mine dewatering, boiler feed water, water supply to high rise buildings, public and industrial water supply, cooling water and hot water circulation, transfer of condensate etc. These pumps are widely used in chemical, petrochemical and general industry water supply. Pumps are used for handling clean water, slightly contaminated water, scrubber water, light chemicals etc.

DESIGN FEATURES

- The ENTITY make pump type MHB are horizontal, side suction, between bearings multistage pumps.

- The head increase takes place in multiple consecutive pumping stages. Multiple impellers are provided for increasing the head.

- Suction casing has inlet nozzle perpendicular to shaft. Delivery casing has outlet nozzle in vertical position. In between stage casings are provided to accommodate impellers and diffusers.

- The rotating assembly is mounted on liberal shaft which is supported by a suitable Anti-friction bearing for taking axial thrust on delivery side and a suitable radial bearing for taking radial load on the suction side.

- Shaft is sealed by stuffing box on each side i.e. Suction side and Delivery side. It is sealed by either Gland Packing or Mechanical seal

Vertical Multistage Pump

Material of Construction

| Delivery Size :- Up to 50 mm |

| Rate of Flow :- Up to 60 m³/h |

| Head :- Up to 300 m |

| Temperature :- Up to 180ºC |

| Working Pressure :- Up to 50 kg/cm²/td> |

APPLICATIONS / LIQUIDS HANDLED

The ENTITY make vertical submerged multistage pumps are most suitable for applications such as firefighting, booster service, mine dewatering, boiler feed water, water supply to high rise buildings, public and industrial water supply, cooling water and hot water circulation, transfer of condensate etc. These pumps are widely used in chemical, petrochemical and general industry water supply. Pumps are used for handling clean water, slightly contaminated water, scrubber water, light chemicals etc.

DESIGN FEATURES

The ENTITY make pump type MVS are vertical submerged multistage pumps specially developed for creating high pressure and for operation under exceptional pressure heads. The pressure increase takes place in multiple consecutive pumping stages. Multiple impellers are provided for increasing the pressure head. Depending on the number of pressure stages, the pump is fitted with either one or two single-row angular contact bearings on the pressure sides. The casing and impeller are completely submerged in the liquid and are suspended through column pipes into the sump or tank. The power is transmitted through a shafting which is supported by bush bearings provided near the impeller and in between two column pipes. The axial load is taken by thrust bearing in the bearing housing provided above support level. Pump is driven by a vertical flange mounted motor which is mounted on a suitable motor stool fixed to the bearing housing.